Contact Lens Design Inspired by the Eye

Developing mechanical and material designs that more closely mimic nature delivers contact lenses that work in tandem with the eye

A happy contact lens patient is one who achieves all-day comfort and great vision. Striving for that twin objective, we looked to the eye itself for design inspiration; we wanted to mimic the ocular anatomy, physiology, and tear film dynamics as closely as possible.

Initial comfort is achieved by most lenses. The real challenge is end-of-day comfort, and that’s what patients need if they are to wear lenses for years. Consider that the human tear film is about 10 µm thick whereas a contact lens is, on average, 80-100 µm thick. Anything that is 8-10 times thicker than the natural tear film is going to be recognized as a foreign body. But the more we can use mechanical and material design to mimic what nature gives us, the greater our ability to make that lens work in tandem with the eye.

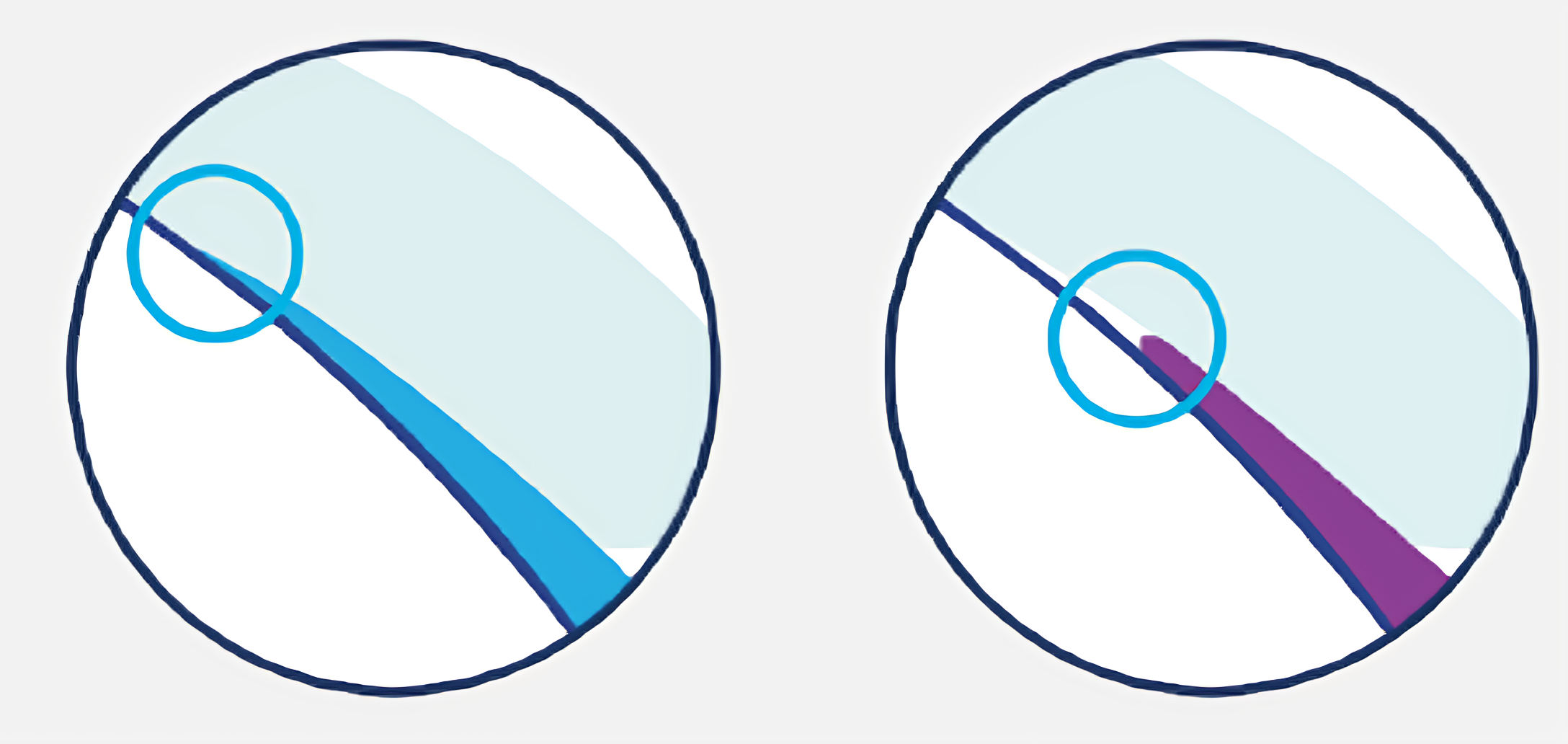

In this regard, a thin, tapered edge (see Figure 1, left) more closely mimics the topography of the anterior eye compared with rounded or blunt-edged lenses (see Figure 1, right). This tapered, “invisible edge” provides a smoother transition for the sensitive lid-wiper region of the upper and lower eyelids to smoothly glide over the lens with each blink. Over the course of a day we blink 12,000–14,000 times (less with screen use!). If this eye-to-lens transition is abrupt (which could occur with rounded or blunt-edged designs), it could result in microtrauma to the lid-wiper region, causing lid-wiper epitheliopathy which is known to result in dryness and discomfort. (If you’d like an analogy to use with contact lens patients: consider riding a bicycle from the street onto the sidewalk multiple times; it’s a lot easier and gentler to access the sidewalk via a smooth ramp rather than bumping over the curb each time.)

Lid interaction is just one feature of a contact lens that can affect comfort. Wettability and lubricity throughout the wear cycle – or how slippery the front surface of the lens is – also greatly impact comfort. The natural tear film is made up of three major components: aqueous (water), lipids, and mucin. We use the wetting agent polyvinylpyrrolidone (PVP) because it has several properties that enhance all-day lubricity and moisture retention to promote comfort. PVP is amphiphilic – both water-loving and lipid-loving – which helps it to interact easily with the aqueous and lipid elements of the tears. In addition, PVP is a demulcent with mucoprotective properties, which makes it gentle on the third major tear component.

These characteristics make PVP-containing lenses very wettable, lubricious, and gentle on the eye. But not all PVP is equal. By incorporating only pure, high-molecular-weight PVP throughout the lens matrix, it is possible to maintain a lower coefficient of friction (CoF) throughout the day. The lower the CoF, the higher the lens lubricity and the better the perceived comfort.

Some years ago, it was determined that the cornea’s natural CoF is 0.015. Many contact lenses can come close to this value right out of the package, but with coatings or other forms of PVP, friction may significantly increase throughout the day. Lenses with high-molecular-weight PVP, however, remain consistently at or below the natural cornea’s CoF throughout a simulated 18-hour wear cycle (1). This affects not just comfort, but also vision. Why? Researchers have shown that higher-order aberrations remain stable in eyes wearing lenses with high-molecular-weight PVP, while they increase throughout the day without PVP (2).

Stability for toric lenses

Almost half of vision-corrected patients (47 percent) have ≥0.75 D of astigmatism in at least one eye (3). Astigmatic patients have better visual acuity, better visual function in low light or glare conditions, and better visual quality of life in a toric lens (4–6). Not surprisingly, astigmatic patients typically prefer their vision in a toric lens compared with a spherical lens (7). However, rotational stability must be quickly achieved and maintained throughout the day, even during blinking, head tilts, and eye movements.

What if we could harness the power of the blink to keep the lens in the correct orientation? Enter “Blink Stabilized Design,” which relies on four slightly elevated stability zones at three o’clock and nine o’clock to quickly realign the lens with each blink. This design also results in minimal lower-lid interaction and provides consistent, clear, and stable vision that isn’t dependent on gravity. Gravity-influenced peri- and prism-ballast designs weight the lower portion of the lens, which works well when the head is upright and the eyes are looking straight ahead, but can be problematic with rapid saccades, large versional tasks, and different head positions; for example, reading in bed or watching television while lying on the couch. Also in contrast to peri- and prism-ballast toric lens designs, blink powered designs provide a prism-free optic zone, avoiding vertical prism disparity, which can cause headaches and discomfort, especially for monocular astigmats (8).

Presbyopic challenges

Aging and the onset of presbyopia present significant challenges for successful contact lens wear. Accommodation declines, of course, which is what drives patients to seek a multifocal contact lens. Multifocal lenses split light to achieve multifocality and, because pupil size changes due to age and refractive error, pupil size needs to be factored into the design of a multifocal lens to maintain the desired distance to near ratio. Additionally, older eyes have reduced tear breakup time and increased light scatter, which can also affect vision. By optimizing lens parameters to more closely match anticipated pupil size by age and refractive error (see Figure 2), we can deliver crisper and more reliable visual performance. I was privileged to lead the team at Johnson & Johnson that developed “Pupil Optimized Design,” for which we won the prestigious Johnson Award in 2015.

This unique optical approach adapts what we know about the physiology of the aging eye to allow the lens to work in harmony with that physiology. The premise of this design is that we cannot use the same lens optical profile for every patient. Accordingly, we developed a multifocal optical design with 183 unique power profiles, thus each lens was designed to maintain the distance to near ratio. We believe this unique patented approach makes fitting our lenses more efficient.

The eye is an amazing organ. By taking our lessons from it, we can develop innovative lenses that benefit patients in terms of both vision and comfort.

References

- O Sterner et al., “Friction measurements on contact lenses in their operating environment: Effect of testing conditions on friction” Invest Ophthalmol Vis Sci 57, 5383 (2016).

- S Koh et al., “Effect of internal lubricating agents of disposable soft contact lenses on higher-order aberrations after blinking,” Eye Contact Lens, 34, 100 (2008).

- G Young, “Prevalence of astigmatism in relation to soft contact lens fitting,” Eye Contact Lens, 37, 20 (2011).

- AA Black et al., “The impact of uncorrected astigmatism on night driving performance,” Ophthalmic Physiol Opt. (2019).

- K Richdale et al., “Visual acuity with spherical and toric soft contact lenses in low- to moderate-astigmatic eyes,” Optom Vis Sci, 84, 969 (2007).

- SM Cox et al., “Efficacy of toric contact lenses in fitting and patient-reported outcomes in contact lens wearers,” Eye Contact Lens, 44 (suppl 1), S296 (2018).

- J Zhang et al., “Epidemiology and burden of astigmatism: A systematic literature review,” Optom Vis Sci, 100, 218 (2023).

- D Jackson, “Vertical heterophoria and susceptibility to visually induced motion sickness. Strabismus,” 20, 17 (2012).

The New Optometrist Newsletter

Permission Statement

By opting-in, you agree to receive email communications from The New Optometrist. You will stay up-to-date with optometry content, news, events and sponsors information.

You can view our privacy policy here

Most Popular

Sign up to The New Optometrist Updates

Permission Statement

By opting-in, you agree to receive email communications from The New Optometrist. You will stay up-to-date with optometry content, news, events and sponsors information.

You can view our privacy policy here

Sign up to The New Optometrist Updates

Permission Statement

By opting-in, you agree to receive email communications from The New Optometrist. You will stay up-to-date with optometry content, news, events and sponsors information.

You can view our privacy policy here